What is a SWMS?

A Safe Work Method Statement (SWMS) is a site-specific document that sets out how high-risk construction work will be carried out safely. It identifies the activity, the associated hazards, the level of risk and the control measures to eliminate or minimise that risk.

A SWMS outlines the sequence of tasks, required competencies, PPE, plant and equipment, permits, isolation steps, emergency procedures and how implementation will be monitored on site. It is prepared by the contractor or PCBU in consultation with the workforce before work starts, used to brief the team at pre-start or toolbox meetings and kept readily available at the work area. The SWMS is a live plan: it must be reviewed and updated when conditions, scope, or methods change and after any incident or near miss. A clear, concise SWMS turns safety requirements into practical steps that crews can follow while meeting WHS regulatory duties.

When a SWMS is required

Under Australian WHS Regulations a SWMS is mandatory for high-risk construction work. Examples include:

Work at height where a person can fall more than 2 m

Work in or near a trench deeper than 1.5 m or a shaft or tunnel

Work in or near a confined space

Structural alterations requiring temporary support

Demolition

Work in or near energised electrical installations or services

Work on or near pressurised gas, chemical or fuel lines

Work in an area with movement of powered mobile plant

Work involving tilt-up or precast concrete

Work with explosives

Diving work

Even when not strictly mandatory many builders now expect a SWMS for complex or multi-stage tasks. The safer practice is to prepare one for all planned high-risk activities.

Why SWMS should be written with your construction contractor

Accuracy

The people who will do the work know the true sequence of tasks, the access issues, the plant that will be onsite, and the points where things typically go wrong. That practical detail turns a generic sheet into a plan that can be followed.

Ownership

When the contractor helps write the controls the crew is more likely to follow them. It becomes their plan and not a document handed down.

Compliance

Regulators expect the SWMS to reflect actual conditions. Collaboration helps capture hazards that only show up during the walk-through.

Clarity for other parties

A shared document lets the principal contractor, client, and other trades understand exclusion zones, traffic management, isolations, crane lifts, and timing.

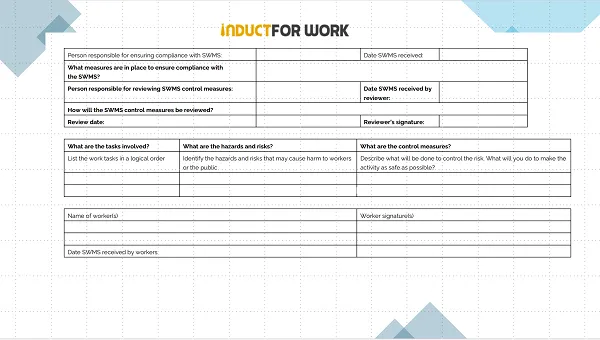

Free SWMS template: structure and guidance

Below is a complete structure you can copy into your own document. After each heading you will see plain-English guidance about what to write.

1) Project and job details

Project name and address

Work area or grid lines and levels

Dates and working hours

Client and principal contractor

Purpose of the job (for example install steel beams to grid B4 using mobile crane)

2) People and responsibilities

Contractor business name and licence details if applicable

Supervisor in charge with phone number

Names of workers on this task

First aider on site

Who has stop-work authority if conditions change

3) Qualifications and training

Construction Induction Card (White Card)

High-risk work licences (for example dogging, rigging, crane, EWP, scaffolding)

Plant VOC or competency records

Job-specific training such as confined space entry or hot works permit

4) Standards and references

List the standards, codes and project rules that apply, for example:

Relevant Australian Standards for the task and plant being used

Codes of Practice for managing risks of the activity

Site rules and permit systems

Manufacturer instructions for plant and equipment

5) Plant, tools, materials

Record what will be used on this job. Include cranes, EWPs, scaffolds, excavators, power tools, traffic management devices, rescue gear, meters and monitors, and lifting equipment with inspection dates where required.

6) Personal protective equipment

Set the minimum for the task: lace-up safety boots, long sleeves, safety glasses, gloves suited to the work, hard hat, high visibility garments, fall-arrest equipment where required, hearing protection if needed, respiratory protection where dust or fumes may be present.

7) Consultation and pre-start

Explain how you will brief the team: toolbox talk before starting each day, sign the SWMS, confirm permits and isolations, check emergency contacts and review any changes in weather, access or nearby trades.

8) Step-by-step tasks with hazards and controls

Create a table with the following columns:

Activity – Hazard – Risk/Consequence – Initial Risk Rating – Controls – Residual Risk Rating.

Keep the activities short and in order. Examples follow; select the ones that match your work and delete the rest.

Pre-start inspection

Hazards: unidentified site risks, poor access, damaged plant

Controls: walk the route, confirm barricades and signage, check plant pre-starts and lifting gear tags, tidy the work areaTraffic management setup

Hazards: interaction with mobile plant and public vehicles

Controls: traffic guidance scheme, trained traffic controllers, plant spotters, separation with barriers, radio commsIsolation of services

Hazards: contact with underground or overhead services

Controls: service locates and permits, mark and verify, isolate where possible, use non-destructive digging near services, no go zones around overhead linesWork at height

Hazards: falls, falling objects

Controls: scaffold or EWP selected and inspected, edge protection or fall-arrest, exclusion zones below, tool lanyards, three points of contact on ladders used only for light short-duration tasksCranage and lifting

Hazards: dropped loads, crush injuries, overturning

Controls: crane set-up on certified ground bearing capacity, lift plan and SWL check, rigging by licensed dogger or rigger, weather limits, exclusion zones, tag lines, clear signalsExcavation and trenching

Hazards: collapse, engulfment, plant interaction

Controls: shoring or battering to angle of repose, trench shields, access/egress ladders, trench observer, spoil at least 1 m back, keep plant away from edgesConfined space entry

Hazards: atmospheric hazards, engulfment, restricted access

Controls: entry permit, gas testing and continuous monitoring, ventilation, standby person, rescue plan and equipment, communication checksHot works

Hazards: fire, burns, fumes

Controls: hot works permit, fire watch, fire extinguishers, spark containment, fume extraction, remove combustiblesStructural alterations

Hazards: collapse, instability

Controls: temporary propping designed by a competent person, exclusion zones, sequencing that maintains stability, inspection before removal of propsHousekeeping and demobilisation

Hazards: slips and trips, leftover hazards

Controls: remove waste and temporary works, reinstate barriers and covers, return plant to storage, sign off permits

Use a simple risk matrix from 1 to 6 or your company matrix. Rate the risk before controls then again after controls so improvements are visible.

9) Live service work policy

State that live service work will not be performed unless there is no reasonably practicable alternative and the law and permits allow it for the situation. If such work is approved record the authorisation steps, additional PPE, barriers, rescue plan, and the competent person supervising. In most cases de-energise or isolate.

10) Permits and isolations

Set out the permits required for this task such as hot works, roof access, confined space, excavation, and service isolation. Record who issues the permit and the permit number. Describe the lockout or isolation method and how the control will be verified.

11) Emergency procedures

Life-threatening emergency: call 000 and advise site location and access point

Falls, crush, or entrapment: stop plant, make area safe, do not move the person unless there is immediate danger

Fire: raise alarm, evacuate to assembly area, use correct extinguisher if trained and safe

Confined space: do not enter for rescue without a plan and equipment

Reporting: notify the site supervisor and complete incident report as soon as practicable

12) Environmental controls

Manage dust, noise, vibration, and runoff. Place spill kits near fuel or chemicals. Stockpile and dispose of waste correctly. Protect drains and sensitive areas. Reinstate disturbed ground and covers.

13) Monitoring and review

Explain how you will check that the controls are in use: supervisor inspections during the shift, stop-work authority for all crew, update the SWMS when conditions change, review after any incident or near miss, and keep records.

14) Sign-off

Add signature lines for each worker on the task, plus the supervisor and where required the principal contractor. Record the revision number and date so the right version stays in circulation.

How to complete the template correctly

1) Start with a site walk-through

Walk the exact work route and laydown areas. Identify access points, exclusion zones, services, ground conditions, and interactions with other trades. Mark hazards and take photos.

2) Write it with the contractor

Sit down together. Agree the task sequence and controls. Remove controls that do not apply. Add the ones that matter on this job.

3) Be specific

“Be careful” is not a control. “Close west gate and implement traffic plan TGS-03 with two controllers UHF radios and barriers” is a control.

4) Keep the scope tight

If the work changes from a short trench to a deep excavation or from a small steel install to a multi-lift crane job stop and revise the SWMS. One page cannot safely cover a different task.

5) Use the same risk matrix as the project

Your builder may have a 1–5 or 1–6 scale. Use their matrix and definitions. Record initial and residual risk.

6) Attach evidence

Include plant pre-starts, lifting gear certificates, VOCs, calibration certificates for monitors, permit copies, and design details for propping or lifting if relevant.

7) Link permits cleanly

Record permit numbers and the key controls from each permit instead of rewriting the whole form. Keep the permit with the SWMS in the site folder or app.

8) Brief the crew each day

Hold a toolbox talk before starting. Walk the job, point out changes, confirm weather limits and wind readings if lifting, verify barricades, and check radios. Each person signs the SWMS for that day.

9) Control public and third-party interfaces

Use barriers, spotters, and signage where the work fronts onto live roads, footpaths, or occupied buildings. Keep a clear line between construction zones and public areas.

10) Hand back safely

Remove temporary works that are no longer needed. Reinstate covers and guards. Remove signage that is no longer valid. Return permits and update drawings or records. Clear the area and confirm the site is safe.

Common mistakes to avoid

Using a generic template without site details

Listing controls that cannot be implemented with the plant or resources available

Skipping isolations or service locates because the task is “quick”

Not maintaining exclusion zones around plant or lifts

Failing to revise the SWMS when the scope or conditions change

Missing daily pre-start briefings and signatures

Poor housekeeping that creates new hazards

Plain-language sample you can copy

Title: SWMS – High-Risk Construction Work

Company: [Your business name]

Job: Install precast panels to Grid C using 100-t mobile crane

Supervisor: [Name phone]

Crew: [Names]

Standards/Codes: Relevant Australian Standards for cranes and lifting plus site rules and traffic plan

PPE: Boots, long sleeves, hard hats, eye and hand protection, fall-arrest where required, hearing protection during cutting or hammering

Plant: 100-t crane, rigging gear with certificates, EWP, radios, traffic barriers

Sequence and controls:

Pre-start and traffic management setup – implement TGS-05 with barriers and two controllers

Crane set-up – certified pads, slew and radius checks, wind limit 10 m/s, exclusion zone in place

Rigging – licensed dogger inspects gear and attaches two leg chain with tag lines

Lifting and placing – clear radio calls, workers outside exclusion zone, spotter confirms line of fire is clear

Temporary bracing – install braces as per engineer design before release

Final fix and check – align, torque to spec, remove tag lines

Demobilise and clean – remove barriers when safe, clear waste and reinstate area

Emergency: call 000 stop plant secure area notify supervisor

Sign-off: crew signatures and date, supervisor approval and date, revision number

Disclaimer

The SWMS provided is a sample only. Your SWMS must suit your site, your scope, your people and your plant. Write it with the construction contractor who will perform the high-risk activity, walk the area together and keep it live throughout the job. A short practical document that crews can follow is far better than a thick generic bundle.

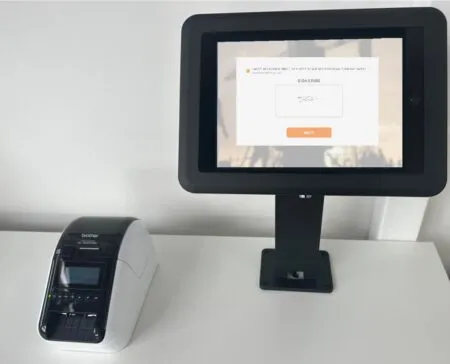

If you want to manage this process without paper INDUCT FOR WORK can run multiple digital SWMS across jobs and sites with sign-off and records all in one place. Contact us today to discuss your SWMS requirements.