Preparing for a Safety Audit in Australia and New Zealand: A Practical Guide for Businesses.

Work health and safety (WHS/OHS) audits are no longer a “nice-to-have” exercise. In Australia and New Zealand, regulators and insurers increasingly expect organisations to demonstrate that they not only have policies in place, but that those policies are lived every day. Audits are one of the key ways to verify this. Done well, they strengthen your safety culture, reduce risks and reassure everyone that the business is under control.

Below is a practical, step-by-step way to prepare for a safety audit, with specific references to the Australian and New Zealand context, and how Induct For Work, particularly its Instant Reporting, can make you audit-ready all year round.

1. Understand what kind of audit you’re facing

Not all safety audits are the same. Before you start preparing, clarify:

Who is auditing you?

Internal audit (carried out by your own WHS team or competent staff)

External audit (consultant, client, certification body or regulator)

What standard or criteria will be used?

In Australia and New Zealand, audits are commonly based on:ISO 45001 Occupational Health and Safety Management Systems

Legacy standards such as AS/NZS 4801

Regulator or insurer audit tools

(e.g. National Self-Insurer Audit Tool in Australia, ACC and SafePlus tools in NZ)

What is the scope?

Whole organisation vs specific sites or departments

Specific risks (e.g. construction, confined spaces, hazardous substances, forestry, agriculture)

Particular accreditation schemes (e.g. Office of the Federal Safety Commissioner, client pre-qualification).

Get the audit criteria in writing. This will shape your preparation and prevent any surprises on the day.

2. Put your paperwork in order

Safety auditors will always start with documentation. In both Australia and New Zealand, they will expect to see a structured WHS / HS management system aligned to legal duties under the WHS Act 2011 (Australia) and the Health and Safety at Work Act 2015 (NZ).

Key documents to gather and update include:

WHS / HS policy signed by senior leadership

Organisational chart showing WHS responsibilities

Risk management procedures and methodology

Safe Work Method Statements (SWMS), Job Safety Analyses (JSAs) or similar

Registers (hazards, risks, chemicals, plant, PPE, training, incidents)

Emergency plans and procedures

Contractor management procedures

Consultation procedures (HSR election, HS committee minutes)

Internal audit and inspection schedules

Make sure version control is clear and that the most recent, approved copies are easily accessible. Induct For Work can help centralise key procedures, forms and records so they are not spread across emails and filing cabinets.

3. Check your risk management is real, not just written

Modern audits focus heavily on how you identify and control risk in practice—not just what’s in your binder. Guidance from Safe Work Australia and WorkSafe NZ emphasises systematic hazard identification, risk assessment and control that is regularly reviewed.

Before the audit:

Review your risk registers:

Are your critical risks (e.g. working at height, mobile plant, electricity, violence, fatigue) clearly identified?

Are controls aligned to the hierarchy of control (eliminate, substitute, engineer, administrative controls, PPE)?

Confirm that controls exist on the ground:

Guarding fitted and maintained

Isolation and lock-out procedures in use

Traffic management plans implemented

Permits to work in place where required

Ensure evidence of review:

Periodic risk review meetings

Changes after incidents or near misses

Updated controls when processes or equipment change

Auditors will often cross-check documents against what they see on site and what workers say in interviews, so consistency is vital.

4. Strengthen training, inductions and competence

In both countries, regulators and audit schemes expect businesses to prove that workers are trained, competent and supervised for the tasks they perform.

Prepare by:

Reviewing your induction program:

Site-specific hazards

Emergency procedures

Reporting of hazards and incidents

Safe work expectations, PPE, fatigue and drug/alcohol policies

Collating training records:

Licences and certifications (e.g. high risk work, forklifts, EWP, working at heights, confined space)

Toolbox talks and safety meetings

Refresher training schedules

Checking contractor onboarding:

Are contractors inducted before starting work?

Are their competencies verified (licences, insurances, SWMS)?

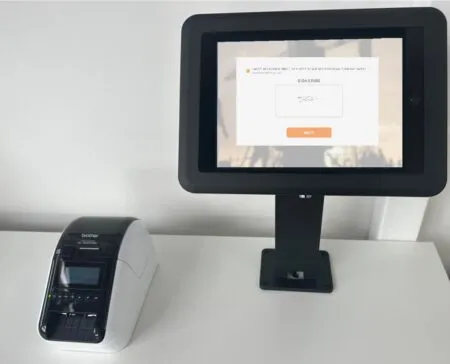

Using Induct For Work allows you to manage inductions for employees, contractors and visitors, store all training records in one place and quickly generate evidence for auditors—showing who has completed what and when.

5. Get control of incidents, hazards and near misses – with Instant Reporting

Incident and hazard reporting is a focal point in most WHS/HS audit tools and standards. Auditors want to see that you:

Encourage reporting of hazards, near misses and incidents

Investigate what happened and why

Implement and track corrective actions

Learn from events across the business

This is where Induct For Work’s Instant Reporting can be a major advantage:

Immediate capture

Workers can log incidents, hazards, unsafe acts or near misses directly from their phone or device—often with photos and location details. This reduces the “I didn’t have time to fill the form” problem and builds a culture of early reporting rather than silence.Consistent, structured forms

You can standardise reporting templates for different event types (injury, property damage, environmental, behavioural safety, etc.), making data easier to analyse and present to auditors.Audit-ready evidence

During the audit you can demonstrate:Number and types of reports received over time

How quickly events are reviewed

Corrective actions assigned, closed out and verified

Trend analysis (e.g. recurring hazards, high-risk locations)

This shows auditors that you don’t just respond to accidents—you actively monitor and improve safety.

Traceable corrective actions

Instead of chasing spreadsheets and emails, action items can be tracked within the system, with responsible persons and due dates clearly assigned. This provides a clean record that auditors can follow from “incident reported” through to “risk reduced.”

6. Engage workers and health & safety representatives

Australian and New Zealand legislation places strong emphasis on worker participation and consultation in health and safety. Auditors will often check:

How workers are consulted (toolbox talks, HS committees, pre-start meetings)

Whether Health and Safety Representatives (HSRs) are elected and trained

How feedback and concerns are captured and addressed

In your preparation:

Gather minutes of safety meetings, HSR election records and communication logs.

Make sure workers know a safety audit is coming and understand its purpose: improving safety, not “catching people out”.

Encourage them to speak openly and honestly with auditors about day-to-day safety practices.

Induct For Work can support this by distributing toolbox talks, policies and updates and capturing acknowledgements and signatures electronically, making your consultation trail easier to demonstrate.

7. Conduct a pre-audit walkthrough

Before the auditor arrives, perform your own mock audit or site inspection:

Walk each area with a checklist based on the audit criteria.

Check housekeeping, signage, guarding, emergency exits, first aid supplies and PPE usage.

Verify that hazardous substances are labelled and stored correctly, and Safety Data Sheets are available.

Confirm that emergency equipment (extinguishers, alarms, spill kits) is in place, accessible and within service date.

Document any issues, assign corrective actions and, where possible, fix them before the official audit. This not only improves your result but also shows auditors that your internal monitoring is active and honest.

8. Get ready for “audit day”

On the day of the safety audit:

Nominate a key contact

Someone who understands your WHS/HS system and can coordinate document access, site escorts and interviews.Have key documents ready

Either in neat hard-copy folders or, more efficiently, in a structured digital system like Induct For Work, where you can quickly retrieve:Induction records

Training histories

Incident and hazard logs

Toolbox talks and communications

Policies and procedures

Brief your leaders and supervisors

Ensure they understand the audit’s scope and can explain how they manage safety in their areas.

Auditors from WorkSafe, SafeWork or third-party providers generally expect business-as-usual operations during assessments, so avoid staging an artificial “show”.

9. After the audit – close the loop

A safety audit is only as valuable as what you do with the findings.

Review the audit report carefully

Identify non-conformances, observations and improvement opportunities.Develop a realistic action plan

Assign responsibilities, due dates and priorities based on risk.Track completion and verify effectiveness

Use your WHS system—or Induct For Work’s action and reporting features—to monitor progress, attach supporting evidence and confirm that controls genuinely reduce risk.Report upwards

Provide concise summaries and dashboards to directors, officers and senior management to help them meet their due-diligence obligations and maintain oversight of safety performance.

How Induct For Work helps you stay “audit-ready” all year

Rather than scrambling in the weeks before an audit, many Australian and New Zealand businesses are moving towards continuous readiness. Induct For Work can support this by:

Delivering and tracking online inductions for employees, contractors and visitors

Maintaining up-to-date training and competency records

Enabling Instant Reporting of incidents, hazards and near misses from any device

Providing centralised storage for policies, procedures, toolbox talks and forms

Creating a clear, traceable record of corrective and preventative actions

By embedding these processes into everyday operations, your next safety audit becomes less about frantic preparation and more about simply showing the truth: a workplace where safety is managed systematically, records are reliable, and issues are dealt with promptly.

That is the kind of story auditors—and more importantly, your workers—want to see.

Disclaimer: The information in this article is provided for general guidance only and does not constitute legal, WHS or professional advice. Safety and workplace obligations may vary between jurisdictions and industries in Australia and New Zealand. Readers should seek their own independent advice from a qualified health and safety professional or legal adviser before acting on any information contained herein. Induct For Work and the author accept no responsibility or liability for any loss, claim or damage arising from reliance on this content.