What can go wrong without it?

Contractors keep Australian business moving. They fill skills gaps, deliver projects, cover seasonal peaks and bring specialist capability that you simply can’t carry on payroll year-round. In manufacturing it might be a maintenance crew coming in for shutdown. In agriculture it’s shearers, pickers, spray contractors and machinery technicians. In local government it’s parks crews, roadworks contractors, waste and fleet services. In defence it can be everything from engineering to ICT, logistics and facilities — often under strict security requirements.

But the reality inside many organisations is this: contractor management has become one of HR’s most painful, time-consuming and risky responsibilities. Not because HR isn’t capable — but because the contractor ecosystem is messy, fragmented and high-stakes. One missing licence, one expired insurance certificate, one unverified induction or one contractor who’s been “treated like an employee” can turn into a safety incident, a legal problem, a reputational crisis or all three at once.

This article looks at what HR teams are up against, where time gets wasted and (most importantly) what can go wrong when organisations engage non-compliant contractors — with practical examples across manufacturing, agriculture, local councils and defence supply chains.

Contractors don’t sit outside your obligations

A common misconception is that if someone is a contractor, the risk sits with them. In Australia, it rarely works like that.

Under the harmonised Work Health and Safety (WHS) framework (implemented in every jurisdiction except Victoria), a PCBU (person conducting a business or undertaking) has a primary duty to ensure, so far as is reasonably practicable, the health and safety of workers while they’re at work — and “workers” includes contractors and subcontractors.

Contracting chains make it more complex, not less. Multiple parties can hold overlapping duties at the same time, particularly where you have principal contractors, subcontractors, labour hire and specialist service providers working on the same site or project. Safe Work Australia’s guidance on “WHS duties in a contractual chain” is blunt about this: the presence of contracts doesn’t remove WHS duties — and individual contractors can be both a worker and a PCBU depending on the arrangement.

For Commonwealth-regulated employers and many large, risk-heavy workplaces, practical guidance is also explicit: contractor management needs to address planning, consultation, competence, supervision, incident notification and evidence-based assurance — not just a signed agreement.

And outside WHS, you also need to get the “employment vs contractor” question right. Sham contracting — treating someone who is effectively an employee as a contractor — is illegal and actively enforced.

In short: contractors are not a loophole. They’re a responsibility.

What HR departments are facing (and why it feels endless)?

1) Admin overload: everything has to be checked, chased, recorded — and rechecked

Contractor compliance isn’t a one-off event. Most evidence expires:

licences and high-risk work tickets

white cards / site cards

insurances (public liability, professional indemnity, workers comp)

police checks / working-with-children checks (where relevant)

training competencies and refresher cycles

medicals / fit-for-work requirements (where relevant)

induction completions (often site-specific)

SWMS / JSA versions and approvals

equipment inspection and calibration evidence

HR (or the business support team adjacent to HR) becomes the “document police”, and it’s rarely supported by clean systems. Evidence arrives by email, as photos, as PDFs, in different naming formats, with missing pages and with expiry dates that are easy to overlook until the wrong day.

2) HR gets pulled into safety, procurement, operations, legal — without clear lines

Contractor management often sits in the cracks between departments:

Procurement signs vendors.

Safety owns site rules and inductions.

Operations want the job done yesterday.

HR is asked to “make sure they’re compliant.”

Legal steps in only after something goes wrong.

Without clear ownership, HR becomes the default coordinator — and the default scapegoat when an auditor asks, “Show me how you verified competence before work started.”

3) Time wasted chasing the same things, again and again

Ask any HR team what burns time, and you’ll hear the same list:

“Can you resend your certificate? The attachment won’t open.”

“That insurance is expired — can you send the current schedule?”

“Your worker’s licence doesn’t match the name on the contract.”

“We need the SWMS updated to match our site controls.”

“They did the induction last year — where’s the proof?”

“The subcontractor changed — now we need all the checks again.”

This is not productive work. It’s repetitive follow-ups, version control, and manual reminders — and it expands exponentially as contractor volumes increase.

4) Patchwork onboarding: every site, manager and project does it differently

Even in well-run organisations, contractor onboarding often depends on who’s running the job. One site has strict pre-qualification. Another site lets a supervisor “vouch for them.” One business unit requires formal sign-off. Another just wants a PO raised.

That inconsistency is where risk breeds — because incidents and investigations tend to focus on what you systematically do, not what you intended to do.

What can go wrong with non-compliant contractors (the part people underestimate)

1) Safety incidents that were predictable — and preventable

Non-compliance is rarely abstract. It becomes physical:

An unlicensed forklift driver.

A contractor doing electrical work without the right competence.

A maintenance contractor bypassing lock-out/tag-out because “we’ve always done it this way.”

A labour hire worker who never received a site induction and walks into an exclusion zone.

Under WHS duties, it is not enough to say, “They’re a contractor; they should know better.” The question that follows is: What did you do, so far as reasonably practicable, to verify competence, manage risk and supervise the work?

In manufacturing environments, the stakes rise fast: plant and machinery, confined spaces, hazardous chemicals, working at heights, hot works and shutdown pressure create the perfect conditions for shortcuts. A non-compliant contractor may be the spark — but your organisation will still be examined for systems, supervision and control.

2) The “contractual chain” trap: subcontractors you didn’t vet (but are now responsible for)

This is a classic failure pattern:

You engage Contractor A (primary vendor).

Contractor A engages Subcontractor B.

Subcontractor B sends Worker C to site.

Worker C is untrained, uninsured or simply unknown to you.

Something goes wrong.

Safe Work Australia’s guidance exists for exactly this reason: in contractual chains, duties can overlap and you need clarity on who is doing what — including consultation, coordination, and verification.

If your contractor management process stops at “We have a signed contract with the head contractor,” you may be blind to the very people doing the highest-risk work.

3) Insurance and liability blow-ups: when the paperwork doesn’t match reality

Non-compliance often shows up when you need it least — right after an incident:

The contractor’s public liability insurance has lapsed.

The named insured doesn’t match the trading entity.

The policy exclusions wipe out coverage for the type of work performed.

The contractor’s workers comp arrangements are unclear, especially across states.

Even if liability ultimately sits elsewhere, the cost and disruption of an investigation, stoppage and claim dispute can be enormous — and HR is usually the first team asked to produce records.

4) Sham contracting and worker misclassification: “We did it to keep things simple”

When organisations “convert” workers into contractors to reduce admin, avoid payroll complexity or meet short-term labour needs, they run straight into legal risk. The Fair Work Ombudsman is explicit: sham contracting is illegal, including misrepresenting someone as an independent contractor when they are actually an employee.

The fallout isn’t just a fine. It can include back-pay, entitlements, tax complications, reputational damage and a breakdown of workforce trust — particularly if it affects vulnerable or dependent workers.

5) Quality failures and operational disruption

Non-compliant contractors don’t only create safety risk. They also create business continuity risk:

In manufacturing: poor workmanship causes repeat downtime, scrap, rework or equipment damage.

In councils: poor contractor performance hits public service delivery and draws community scrutiny.

In agriculture: non-compliant chemical application can create contamination, export issues or biosecurity breaches.

In defence supply chains: inadequate security controls can compromise projects, data and tender eligibility.

And unlike internal staff, contractors can disappear after the job — leaving you to deal with warranty disputes, rectification, and documentation gaps.

6) Security and information risk (especially in government and defence-linked work)

Government and defence contracting adds another layer: information, personnel and physical security obligations.

The Defence Industry Security Program (DISP) exists to help entities understand and meet security obligations when engaging in Defence tenders, contracts and projects. Defence and performance audits have previously highlighted how hard it can be to monitor compliance with contracted DISP requirements at scale.

For HR and contractor onboarding, that translates into practical risk: who gets access to sites, systems, drawings, schematics, sensitive project details or controlled assets — and whether your contractor’s controls match the obligations of the work.

Industry snapshots: where contractor non-compliance bites hardest

Manufacturing: shutdowns, maintenance, and high-risk work

Shutdowns compress weeks of work into days. Everyone is tired. Production wants restart. Contractors are working alongside internal teams under time pressure.

Common failure points:

outdated or generic SWMS that don’t match your plant hazards

contractors unfamiliar with your permit-to-work systems

competence not verified for high-risk activities

inadequate supervision when multiple contractors overlap

When something goes wrong in manufacturing, investigations move quickly to systems: what was checked, who signed off, what induction was done, and how control was maintained.

Farming and agriculture: seasonal labour, remote work, and “normalised risk”

Agriculture has a culture of getting the job done — often in remote conditions with fewer formal controls and a reliance on experience.

Contractor challenges often include:

seasonal surges (many new faces at once)

limited connectivity for onboarding and recordkeeping

machinery and vehicle hazards

fatigue, heat stress and working alone

chemical use and application competence

Here, non-compliance can mean injury — but it can also mean farm business disruption through product contamination, supply chain rejection or regulator action after a serious incident.

Government and city councils: public scrutiny, procurement rules, and duty of care

Councils sit in a high-visibility environment. Contractor issues don’t stay internal — they show up as:

public complaints

media attention after incidents

probity concerns in procurement

audit findings around contractor governance

Councils also manage diverse worksites: depots, roadworks, parks, libraries, community facilities, waste transfer stations — each with different risks and different types of contractors.

Strong contractor management here is as much about defensible governance as it is about WHS.

Defence contractors: access, security, supply chain assurance

Defence-linked work amplifies the cost of failure. One contractor with weak security posture can put a whole project at risk.

Contractor management commonly needs to address:

security requirements (including DISP expectations where applicable) Defence

controlled access to sites and systems

personnel vetting processes (role-dependent)

segregation of information and secure handling practices

subcontractor management (the weakest link problem)

In this environment, “paper compliance” is not enough — you need confidence that controls are real, maintained and auditable.

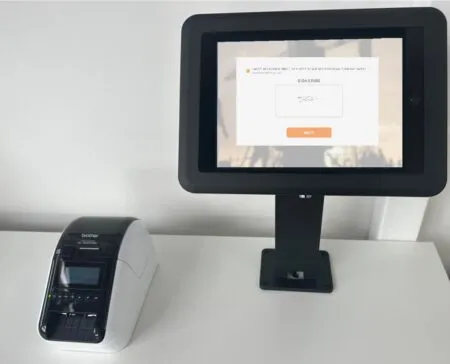

Practical controls that cut HR workload and reduce risk — with INDUCT FOR WORK

The strongest contractor management system follow a simple, proven sequence: qualify before engagement, induct before access, supervise during work and close out properly. The challenge for HR is making that sequence consistent across every site and every manager — without living in email follow-ups.

INDUCT FOR WORK supports this end-to-end workflow in one place, so contractor compliance becomes a repeatable process instead of a daily chase.

1) Fit-for-purpose pre-qualification (before anyone starts)

Start by setting clear minimum standards based on contractor risk level (low-risk vs high-risk) and role type — and collect evidence up front, not after the contractor is already on site.

With INDUCT FOR WORK, contractors can upload and maintain their required documents digitally, while your team verifies them against your rules.

Typical pre-qualification evidence includes:

Insurance certificates (e.g., public liability, professional indemnity where relevant)

Licences and competencies aligned to the work being performed

Safety documentation (SWMS/JSA, procedures, relevant policies)

History and references for higher-risk work categories

Subcontractor declarations and rules around notification and approval

2) One onboarding pathway, with clear “go/no-go” gates

The biggest risk in contractor onboarding is the informal workaround: “They can start anyway — we’ll get the paperwork later.” That’s where organisations get exposed.

INDUCT FOR WORK helps you build a single onboarding pathway with clear gates such as:

documents submitted and verified

online induction completed

role or site-specific training completed

supervisor assigned

access granted only once requirements are met

This is where HR stops chasing — because the workflow enforces the process automatically.

3) Controlled SWMS and site rule versions (so you can prove what was in place)

When site rules change, contractors must be working from the latest version. When a SWMS changes, you need an auditable record of what changed, who approved it and when.

INDUCT FOR WORK supports cleaner compliance by keeping induction content and supporting documents organised and traceable — which becomes critical during incident investigations, audits and contract disputes.

4) Active monitoring (not “set and forget”)

Contractor risk shifts over time. People change. Subcontractors appear. Documents expire. If you’re relying on spreadsheets and inbox reminders, you’ll eventually miss something.

A stronger approach includes:

expiry alerts for licences, insurances and competencies

periodic re-verification for long-running contractors

spot checks and ongoing compliance checks on-site

supervision and toolbox talks integrated into the job rhythm

With INDUCT FOR WORK, reminders and records are centralised, so compliance stays current without constant manual follow-up.

5) Clean offboarding (so contractors don’t drift into unmanaged access)

When a contractor finishes, close the loop properly:

remove access

close permits and job sign-offs (as required)

archive evidence and completion records

capture lessons learned

record performance (good and bad)

A disciplined offboarding process prevents “permanent contractors” drifting into unmanaged status — and helps you make better vendor decisions next time.

Contractor management isn’t admin — it’s risk control

HR teams carry the burden of contractor management because the work is repetitive, fragmented and often lacks clear process gates. But contractor non-compliance is also one of the fastest ways for organisations to be exposed — through safety incidents, legal breaches, insurance gaps, quality failures, security issues and reputational damage.

The organisations that get this right treat contractor management as a disciplined, repeatable system — and INDUCT FOR WORK gives you the structure to run that system consistently across every site, every contractor and every time.