2026 guide to identifying hazards, controlling risk and training your workforce

Workplace hazards are things and situations that could harm a person at work. In 2026 the challenge is rarely a lack of information. The challenge is consistency across sites and teams, plus controls that hold up on busy days.

This guide explains the most common workplace hazards, how to identify them early, how to apply practical controls and how to train staff and contractors so safe work becomes routine. It also explains how INDUCT FOR WORK helps you deliver online training, confirm understanding with quizzes and keep completion records ready for audits and client checks.

Key takeaways

Hazard management works best when you identify hazards, assess risk, control risk, then review controls regularly

Eliminating risk is the best control. If you cannot eliminate, use the hierarchy of controls and avoid relying only on procedures and PPE

Electrical risks and plant risks are common across Australian workplaces and are specifically covered in national guidance

Online induction and training is most effective when it is short, role based and measured with simple checks for understanding

INDUCT FOR WORK helps standardise training across roles and sites, reduces chasing with reminders and keeps proof ready records

Contents

What workplace hazards are in 2026

How to identify hazards before incidents happen

Hazard controls that actually work in day to day operations

Workplace hazards checklist by hazard type

Training, reporting and records that reduce repeat incidents

FAQ

1) What workplace hazards are in 2026

Workplace hazards appear in predictable groups. Your site might have additional hazards, but these categories cover most businesses:

Electrical hazards

Plant and machinery hazards

Vehicles and mobile plant hazards

Slips, trips and falls

Working at height

Manual tasks

Chemicals and hazardous substances

Noise and hearing risk

Heat, cold and weather exposure

Confined spaces and restricted access areas

Fatigue and reduced alertness

A good program focuses on the highest risk tasks first, then expands. That approach is faster to roll out and easier to sustain.

2) How to identify hazards before incidents happen

Hazard identification works best when it is routine, simple and supported by supervisors.

Use a mix of methods:

Pre start checks in work areas and on equipment

Task checks before non routine work such as repairs, fault clearing or changes to setup

Worker and contractor reporting, because they see hazards first

Review of incident and near miss patterns to spot repeat issues

Checks after change such as new equipment, new layout or new procedures

Safe Work Australia outlines a step by step approach: identify hazards, assess risks, control risks, then review control measures.

A practical way to turn this into habit is to use four simple questions:

What can hurt someone here

How could it happen

Who is exposed and when

What controls could fail under pressure

If you want reporting to work, make it easy and respond quickly. When people see action taken, they keep reporting. When nothing happens, reporting stops.

3) Hazard controls that actually work in day to day operations

Controls fail when they rely on perfect behaviour. That is why the hierarchy of controls matters.

Safe Work Australia states eliminating the risk is the best control. If you cannot eliminate, you must minimise risk so far as is reasonably practicable using the hierarchy of control measures. It also notes administrative controls and PPE are least effective because they do not control the hazard at the source and rely on behaviour and supervision.

A practical control approach looks like this:

Remove the hazard where possible

Replace it with a lower risk option

Isolate people from the hazard using barriers, guarding, separation or exclusion zones

Use engineered controls that reduce exposure and prevent contact

Use procedures, permits, supervision and signage to support higher controls

Use PPE as the last line of defence, not the main control

Training should explain what the control is, why it exists and what happens when it is bypassed. That makes compliance more likely, even on busy days.

4) Workplace hazards checklist by hazard type

Electrical hazards

Electrical hazards can lead to shock, burns, fire and fatal incidents. National guidance explains that electrical work is dangerous and that businesses must keep workers safe from electrical risks.

Practical controls that match Australian guidance:

Ensure electrical equipment is safe to use. If it is unsafe it must not be used and should be disconnected until repaired or tested safe by a competent person

Use only licensed or registered electricians for electrical work

Inspect leads for damage before use and remove damaged leads

If an RCD, circuit breaker or other device disconnects power, work out why it tripped before switching back on

Arrange leads to avoid damage by keeping them away from doorways, sharp edges and walkways and using hangers or protection where needed

Training points to include:

What “unsafe equipment” looks like on your site

Who can isolate and who can repair

What to do after a trip event

How to report electrical hazards quickly

Plant and machinery hazards

Safe Work Australia defines plant broadly as machinery, equipment, appliances, tools and anything fitted or connected to them. It notes plant is a major cause of death and injury in workplaces.

Common plant hazards include entanglement, crushing, shearing, cutting and ejected parts. Many incidents occur during cleaning, fault clearing, adjustment or maintenance.

Controls that work:

Guarding that prevents contact with moving parts or controls access to dangerous areas

Interlocks where access is required during operation, cleaning or maintenance

Guarding that is solid, securely mounted, hard to bypass and properly maintained

Clear isolation steps for maintenance tasks

Pre start checks that include guarding condition and interlock function

Training points to include:

Never bypass guarding

Never reach into moving parts

Stop, isolate, verify, then work

Report missing or damaged guarding immediately

Vehicles and mobile plant hazards

Mobile plant such as forklifts, cranes and elevating work platforms can cause serious injury and death. Common risks include collisions, overturning, objects falling on operators and operators being ejected.

Controls that work:

Separate pedestrians and vehicles with walkways, barriers and clear exclusion zones

Set site traffic rules and keep them consistent

Use spotters where needed and define responsibilities clearly

Control reversing with designated zones and clear visibility rules

Use immobilisation practices for parked or serviced equipment

Training points to include:

Speed limits and right of way rules

Blind spots and reversing rules

Loading zone rules

What to do when rules conflict with time pressure

Slips, trips and falls

These injuries remain common across offices, warehouses, venues and worksites.

Controls that work:

Keep floors clean and dry and clean spills quickly

Use slip resistant surfaces in wet areas

Manage cords and hoses to remove trip points

Maintain steps, handrails and lighting

Keep walkways clear of stored items

Training points to include:

What must never be stored in access ways

How to report damaged flooring or poor lighting

Footwear expectations for each area

Working at height

Falls can cause severe injury even from relatively low heights. Controls should focus on avoiding height work where possible, then using higher reliability controls.

Controls that work:

Avoid height work by doing the task from ground level where possible

Use platforms with guardrails for routine work

Use suitable access equipment and keep ladders for short duration tasks where appropriate

Use fall protection systems where required by your site method

Training points to include:

When ladders are acceptable on your site and when they are not

How to inspect access equipment before use

How to plan the task so people are not rushed

Manual tasks

Manual tasks can cause strains and injuries through lifting, pushing, pulling, repetition and awkward posture.

Controls that work:

Use mechanical aids where possible

Reduce load weight and improve storage height and access

Adjust work layout to reduce reaching and twisting

Rotate tasks where practical

Fix the task design rather than relying only on lifting technique training

Training points to include:

When to ask for help

How to use aids correctly

How to report a task that is hurting people

Chemicals and hazardous substances

Chemical hazards include fumes, burns, skin exposure and unsafe storage risks.

Controls that work:

Keep labels intact and store chemicals correctly

Provide ventilation where required

Use the correct gloves and eye protection for the substance

Keep spill kits ready and train people to use them

Keep Safety Data Sheets accessible

Training points to include:

How to find the Safety Data Sheet

What to do after a spill

Correct storage and decanting rules used on your site

Noise and hearing risk

Noise hazards are common in workshops, construction, manufacturing and warehousing. Hearing loss is permanent.

Controls that work:

Reduce noise at the source where possible

Maintain equipment to avoid unnecessary noise

Use barriers and distance to reduce exposure

Set hearing protection zones and enforce them

Provide suitable hearing protection and train correct fit

Training points to include:

Where hearing protection is required

How to fit and maintain hearing protection

How to report noisy equipment that needs maintenance

Heat, cold and weather exposure

Weather exposure affects outdoor crews, warehouses and hot work areas. Heat risk rises for new starters and those returning after time away.

Controls that work:

Provide water, shade and rest breaks

Schedule heavy work for cooler times where possible

Provide suitable gear for cold and wet conditions

Monitor people who are not acclimatised

Teach supervisors early warning signs and response steps

Training points to include:

Hydration and break expectations

When to stop work and escalate

Symptoms that require urgent action

Confined spaces and restricted access areas

Confined space hazards can include lack of oxygen, toxic atmosphere, engulfment and restricted exit.

Controls that work:

Permit process where required by your procedure

Atmospheric testing where required

Ventilation and standby support where needed

Practical rescue planning

Restrict access to authorised personnel

Training points to include:

What your site classifies as a confined space

Who can authorise entry

What steps must be completed before entry

Fatigue and reduced alertness

Fatigue increases risk in driving, machinery operation and decision making. It can build during overtime, long shifts, early starts and night work.

Controls that work:

Plan rosters to avoid extreme hours where possible

Manage breaks and recovery time

Encourage early reporting before fatigue becomes dangerous

Train supervisors to recognise warning signs

Add check in steps for high risk tasks

Training points to include:

Warning signs of fatigue

How to speak up early

Which tasks must stop when alertness is low

5) Training, reporting and records that reduce repeat incidents

Training works when it is short, role based and supported by simple checks for understanding. It must also cover non routine tasks such as fault clearing and maintenance because that is where many incidents happen.

A practical training approach:

Core hazard training for everyone

Role modules for higher risk tasks

Short quizzes to confirm understanding

Refreshers when procedures change and on a set cycle

Clear records showing who completed what and when

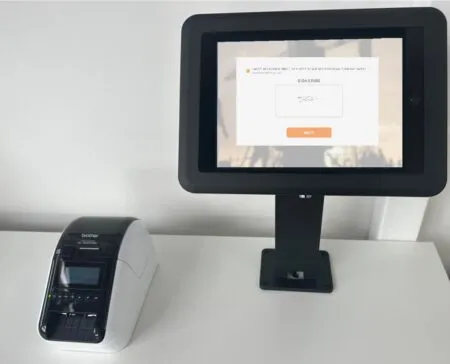

INDUCT FOR WORK supports this workflow by helping you deliver online training, assign modules by role and site, invite staff and contractors quickly, use quizzes to confirm understanding and keep completion records ready for audits and client checks.

Frequently asked questions

Workplace hazards are things and situations that could harm a person. They include electrical risks, plant hazards, vehicles, falls, chemicals, noise and weather exposure.

Start by eliminating the risk where possible. If you cannot eliminate, use the hierarchy of controls and focus on higher reliability controls before relying on procedures and PPE.

Not always. Safe Work Australia notes you may not need a risk assessment if hazards, risks and controls are well known. You still need to control risk and review controls.

Make reporting simple, respond quickly and close the loop so people see outcomes. Use Induct For Work Incident and Hazard Reporting.

It helps you deliver hazard training online, assign training by role and site, confirm understanding with quizzes and keep proof ready records without paperwork.

If you want workplace hazard training that is consistent across sites and teams, use INDUCT FOR WORK to build your hazard modules, invite your workforce, track completion and keep tidy records.